The HPP Protein Plant

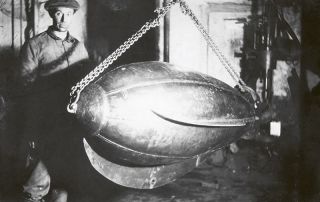

From the very beginning, Héðinn’s ties to the fisheries sector have been strong. Among other things, Héðinn carried out repairs on trawlers and fishing vessels in the Icelandic fleet.

It can be said that for a whole century there has been a constant interplay within the fishing industry between Héðinn and the sectors of fishing and fish processing, with Héðinn serving as a pioneer in many technological revolutions and advancements in the industry.

In this way, Héðinn has had a hand in the modernization of all traditional fishmeal factories in Iceland, including the electrification of the drying process.

Icelandic Skill and Innovation

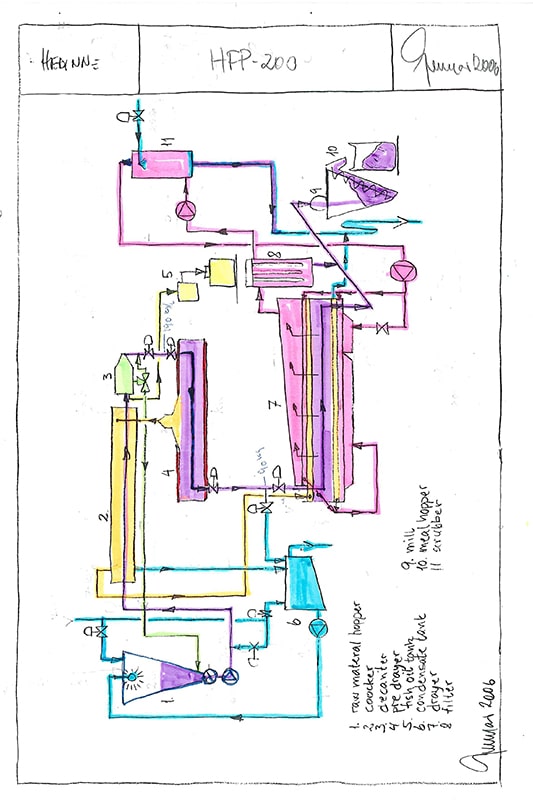

Héðinn’s latest contribution is the HPP protein plant, where Icelandic craftsmanship and ingenuity come together in a high-tech sector. The plant is the result of about fifteen years of innovation and development work at Héðinn.

From the outset, emphasis was placed on creating value from fish species and those parts of the fish not considered suitable for human consumption. Prior to the HPP solution, there had been a marked shortage of small-scale factories on the market. The aim was to design a plant that would meet all environmental requirements, require little manpower, and be capable of producing meal and oil from raw material that could be used not only for feed production but also, where possible, for human consumption.

The prototype of the HPP plant was launched in 2017 on Sólberg ÓF-1 from Ramma hf. By the time this is written, in March 2022, HPP plants have been sold to fishing companies and land-based processing plants in the United States, Germany, the Faroe Islands, England, Finland, France, and Norway.

Héðinn Protein Plant The original idea for HPP dates back to 2006. The drawing is by the creator of the HPP solution, Gunnar Pálsson, engineer and Héðinn’s development manager for many years.

Processing capacity from 10 to 400 tons per day

Three HPP plants have been sold in Iceland. Among them is one on board the most advanced fishing vessel in the North Atlantic, Ilivileq, owned by Brim, which is also a Kongsberg vessel. In Neskaupstaður, a 380-ton HPP plant is being built for Síldarvinnslan. The processing capacity of these plants ranges from 10 to 400 tons per day, depending on their size.

The strengths of the HPP protein plant lie in the fact that it requires at least 30 percent less space, has 30 percent fewer components, and consumes 30 percent less energy than conventional fishmeal factories. In other words, the HPP plant is a much more compact design than its main competitors. A traditional fishmeal factory has 21 main components and requires energy input at eight points. By contrast, the HPP plant has only seven main components and requires energy input at just two points.

At Sea and on Land The HPP plant is produced in different sizes depending on whether it is intended for installation on board a vessel or on land. Its processing capacity ranges from 10 to 400 tons per day. The photo shows the HPP system below deck on the trawler Ilivileq. Photo: Páll Stefánsson / Héðinn

At Sea and on Land The HPP plant is produced in different sizes depending on whether it is to be installed on board a vessel or on land. Its processing capacity ranges from 10 to 400 tons per day. The photo shows an HPP factory at Havsbrun in the Faroe Islands. Photo: Pól Huus Sólstein / Héðinn

100 Percent Utilization of the Catch

When an HPP plant is installed on board a vessel, not a single fin of the catch is thrown overboard. The fish is utilized 100 percent. What was once discarded is turned into great value. In this way, protein production can be increased without additional fishing. One of the greatest environmental issues facing today’s generations is to transform protein production methods so that they become sustainable. By making full use of the catch, respect is shown for the natural resource and the environment.

It can be estimated that the products of HPP plants amount to seven to ten percent of the catch value landed, depending on whether the plant is certified for human consumption or not. The products are further processed either into high-quality protein meal for feed or into fish oil for human consumption.

At the turn of the year 2022, the company HPP Solutions was established, which has since become an independent entity.

The Most Advanced Fishing Vessel in the North Atlantic The trawler Ilivileq is packed with equipment in which Héðinn has a part. On board is an HPP protein plant, and the vessel’s design and all of its machinery come from the Norwegian company Kongsberg, for which Héðinn is the agent. Here we see Ilivileq in Reykjavík harbor; it is operated by Brim’s subsidiary Arctic Prime Fisheries in Greenland. Photo: Páll Stefánsson / Héðinn

Héðinn for over 100 years

Send us a message

Fill out the Form