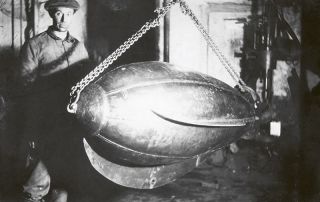

Representative of an older era The waste treatment plant in Reykjavik Skarni, began operations in 1959 and took in all the city’s refuse. This marked a significant milestone in the town’s public health and cultural affairs. The plant’s machinery was manufactured at Héðinn. The station converted the waste into fertilizer (skarni), which was used for cultivation on land in Reykjavik. The facility was considered such a revolutionary innovation that a press conference was held at its opening, and the following day an article appeared on the front page of the newspaper Morgunblaðið with the headline: “The ash heaps abolished completely and entirely.” Photo: Author unknown / Héðinn

Skarni and Kalka

Héðinn took part in developing and building a new and modern waste treatment plant in Suðurnes, replacing an older facility that had been in operation for a quarter of a century.

Waste management is one of the greatest environmental issues of any era, and Héðinn has taken part in the design and construction of waste incineration plants at various periods throughout its history.

The Kalka incineration plant in Suðurnes began operations on April 1, 2004. It is rated to burn up to 12,300 tons of waste per year and is equipped with highly advanced flue gas cleaning technology to keep emissions from the plant to an absolute minimum. The company was previously called Sorpeyðingarstöð Suðurnesja sf. and was founded on August 1, 1978. That earlier incineration plant was officially commissioned on August 31, 1979.

At Kalka, waste incineration takes place under oxygen-starved conditions (in fact, a form of pyrolysis is taking place), after which oxygen is injected into the flue gases. This causes the temperature to rise dramatically, ensuring that everything in the gases that needs to be burned is fully combusted.

The energy is used to produce high-pressure steam, which drives a power plant, and the surplus energy is utilized to heat the grounds around the facility.

The name refers to a cairn called Kalka, which once marked the boundary between municipalities in Suðurnes, but has since disappeared beneath the runways of Keflavík Airport. The cairn was whitewashed and served as a well-known landmark from the sea.

At Kalka, all waste from municipalities and companies within the plant’s service area is received in accordance with the price schedule. The facility also operates a drop-off site for the public, as well as in Grindavík and Vogar, where local residents can bring household waste for disposal and recycling. The incineration plant is also equipped to handle infectious waste as well as various categories of hazardous materials generated in Iceland.

High-tech waste incineration, past and present Inside the Kalka waste incineration plant in Suðurnes, designed and built by Héðinn. The plant was commissioned in 2004 and was far ahead of its time in Iceland. It produces electricity and hot water and remains the most advanced waste incineration facility in the country.

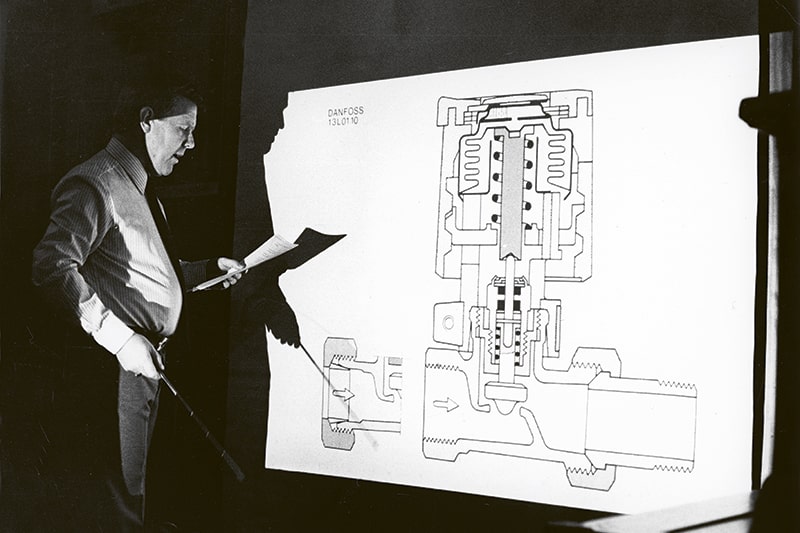

Gísli – Danfoss In 1991, one million Danfoss radiator valves had been sold in Iceland. The achievement was considered remarkable, and Gísli Jóhannsson at Héðinn received special recognition for his contribution to the outstanding success in saving hot water used for heating homes in Iceland. Photo: Author unknown / Héðinn

Hot Work The picture on the left shows Sigurjón Guðnason, who was foreman and manager of Járnsteypan for decades. In the photo, he is skimming impurities off the molten metal in the crucible. On the right is Victor Strange at Járnsteypan, pouring 900-degree molten metal into a sand mold. Photos: Kristján Gíslason / Héðinn

Metal Smelting In this photo from Járnsteypan's workshop, from left: Victor Strange, Sæmundur Sæmundsson, foreman for decades, and Sigurjón Guðnason, employee and foreman throughout his entire career. Járnsteypan was the foundation of Héðinn’s production during and after the mid-20th century. All of the company’s manufactured products originated, to a greater or lesser extent, from the foundry. For many years, the metal was smelted in a cupola furnace fired with coke. The coke, together with the pig iron, was hoisted by hand to the top of the furnace—a very demanding task. Later, production was modernized with electric smelting. This photograph was taken around 1980. Photos: Jóhannes Long / Héðinn

Héðinn 100 ára

Send us a message

Fill out the Form