Project Description

A key player in the development and construction of fishmeal processing plants

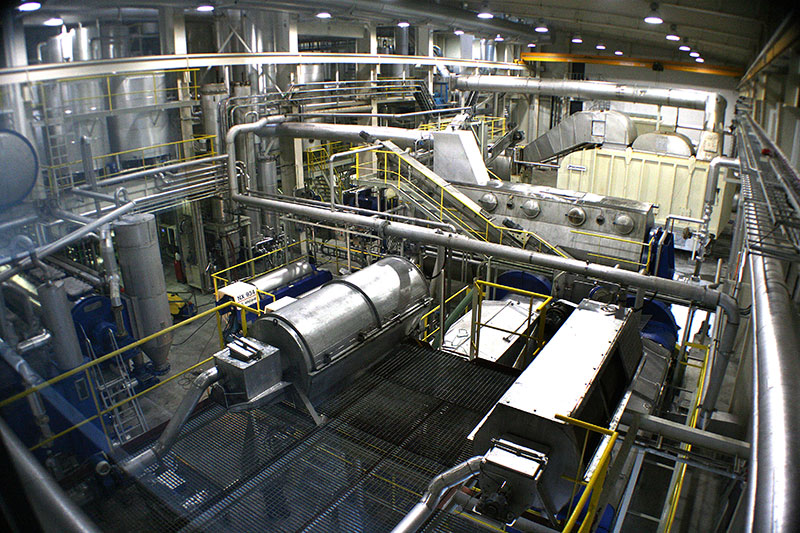

Héðinn has played a major role in the development and construction of ten fishmeal factories operating in Iceland. This is the result of decades of successful collaboration, which has contributed in increased efficiency, operational reliability, energy savings, and more valuable products.

Over the years, fishing companies have entrusted Héðinn’s specialists with full responsibility for the construction, upgrades, and modifications of fishmeal factories. Within Héðinn, this has led to the development of extensive expertise in the production process of fishmeal and fish oil, expertise built on collaboration, trust, and a shared commitment to continuous improvement. This knowledge became the foundation for the development and construction of the HPP – Héðinn Protein Plant – an innovative processing system for producing fish oil and fishmeal, designed for use both at sea and on land.

Héðinn services thereby two production methods in this sector: The traditional process and the HPP process. There is significant activity among fishmeal producers across Iceland, with many companies undertaking major upgrades and expansions. One example is Síldarvinnslan in Neskaupstaður, where a large part of the company’s traditional fishmeal plant is being renewed, while a new HPP facility is being installed alongside it.

HPP – Héðinn Protein Plant

In 2010, Héðinn began developing a new approach to fishmeal and fish oil production, with a focus on reducing energy consumption and operational footprint while delivering higher-value products. The result is the HPP – Héðinn Protein Plant, which uses 30% less energy, requires 30% less space, and operates with 30% fewer processing units than conventional systems.

The goal was to offer the HPP system in various capacities, all based on the same core design. Additionally, the HPP was developed to be fully operational both at sea and on land. The first HPP plant at sea was commissioned onboard the vessel Sólberg ÓF in 2017.

The HPP production process is based on a method where liquid is not mechanically pressed from the raw material during pre-processing, but instead relies on two-stage steam drying powered by electricity. This makes the entire process simpler, reduces energy demand, and requires less space for the equipment. As a result, the HPP system is well suited for use at sea, enabling 100% utilization of all raw material brought onboard. The first fully operational HPP plant had a capacity of 7 tons of raw material per day, while the most recent systems can process up to 380 tons per day. The largest HPP plant at sea to date handles 100 tons per day and is installed on the factory trawler North Star, operated out of Alaska.

The HPP plant is built on a high degree of automation and remote monitoring. During operation, manual intervention is typically only required for bagging the meal and oil. The HPP system is designed to produce high-quality fishmeal using low-temperature drying and premium-grade fish oil.

HPP's website: proteinplant.is

Fishmeal and fish oil manufacturers in Iceland

- Síldarvinnslan – Neskaupsstaður

- Síldarvinnslan – Seyðisfjörður

- Loðnuvinnslan – Fáskrúðsfjörður

- Brim – Vopnafjörður

- Brim – Akranes

- Ísfélag Vestmannaeyja – Þórshöfn

- Ísfélag Vestmannaeyja – Vestmannaeyjar

- Vinnslustöðin – Vestmannaeyjar

- Skinney Þinganes – Höfn, Hornafjörður

CONTACTS

Send us a message

Fill out the Form