Project Description

Mechanical Department

The mechanical department serves clients both at sea and on land, working closely with the marine engineering specialists in Héðinn’s ship division. Projects include engine and gearbox repairs, as well as refurbishment, installation, and maintenance of various mechanical systems for energy companies and heavy industry. The department is staffed by marine engineers, mechanics, and students.

Specialized machinery

Héðinn’s Mechanical Department is equipped with a wide range of specialized machinery designed to handle complex or highly specific tasks, both on land and at sea. This advanced equipment enables high precision and ensures reliable performance. All machinery is operated by Héðinn’s skilled mechanical specialists, ensuring optimal use and quality outcomes.

3D scanner

| Usage | Technical description |

|---|---|

| Faro Focus S70 3D scanner is used for large-scale projects where complex equipment must be installed in confined spaces. A precise 3D scan of the area allows for high accurate placement of equipment during the design phase, ensuring optimal results. The resulting 3D model also simplifies future modifications and add-ons. | Faro Focus S70 is a laser scanner with a range of up to 70 meters and ±1 mm accuracy within 10 meters. The same space is scanned from multiple angles to create a comprehensive 3D view. The data is imported into Faro Scene software, which generates a 3D model that is then transferred into design software. Integrated high-resolution camera captures surface textures and colors, producing a realistic and detailed visual representation of the scanned environment. |

Flexible borescope with video recording

| Usage | Technical description |

|---|---|

| Videoscope with a flexible arm is used to inspect the condition of equipment and mechanical systems in areas that are otherwise inaccessible — for example, the interior of cylinders. The tip can be remotely controlled using a joystick, allowing full 360-degree viewing capability. | The Olympus IPLEX G is a high-performance videoscope featuring a 2-meter-long flexible probe with a diameter of just 4 mm. At the tip is a camera with 5x zoom, integrated LED lighting, and a microphone for audio recording. The probe’s distal end can be articulated in all directions using a joystick control on the device. It features a 4.3-inch touchscreen, HD video resolution (765×576), and an HDMI output for real-time monitoring on a tablet. The system supports video recording to an SD card and allows for still image capture during inspections. |

Laser alignment tool

| Laser alignment tool |

|---|

| The most precise measurement system available on the market, featuring wireless sensors connected to the measurement computer. Offset: 0,5 micron(<0,15%), Angular: 0,007mm(<0,75%). Wireless sensors have a range of 30 meters. |

Vibration sensor

| Vibration sensor | Balancing |

|---|---|

| The Betavib Collector Analyzer is the fastest 3-axis vibration measurement system on the market. It features a built-in bearing frequency database and stores historical measurement data for trend analysis. The system also provides warning thresholds. | Offers on-site balancing, allowing machinery to be balanced without removal or transport to a workshop. Reduces a lof of time and cost. |

Jacking station for up to four jacks

| Usage | Technical description |

|---|---|

| Jacking Station with Manifold for Up to Four Jacks

Each jack is equipped with a pressure gauge to monitor the load and ensures precision. |

Manifold for Four Jacks. Héðinn offers a range of jacks from 10 to 60 tons, as well as two 100-ton jacks. |

Force gauge / scale

| Usage | Technical description |

|---|---|

| Force Gauge (Scale) up to 50 Tons with Wireless Readout. | Wireless readout, USB connectivity for data download, and displays accumulated force/weight, indicates overload conditions at 110% of rated capacity and offers accuracy of ±0.2% of full scale. |

High-pressure equipment for oil flotation systems

| Usage | Technical description |

|---|---|

| High-pressure oil injection for mounting and dismounting bearings, gears, rudders, and various other components. | High-pressure pump, connecting equipment, and jacks for dismounting or mounting. |

Cylinder Pressure Indicator

| Usage | Technical description |

|---|---|

| Measures combustion pressure in main and auxiliary engines, regardless of fuel type. Generates a graph that clearly shows whether engine timing is correct as well as pressure differences between cylinders. Enables improved engine performance and reduced operating costs. | Connects to indicator valve and measures combustion pressure. Operates on the same fundamental principles as compression testing in automotive engines. Results can be downloaded to a computer. |

Strobe light

| Usage | Technical description |

|---|---|

| Strobe light with adjustable frequency makes moving engine components appear stationary, enabling easier visual inspection. | Flash Frequency from 30 to 300,000 per minute, with an accuracy of ±1 flashes per minute or ±0.01% of the reading, whichever is greater. External sensor for measuring rotational speed. LCD monitor, and ten stored measurements records. |

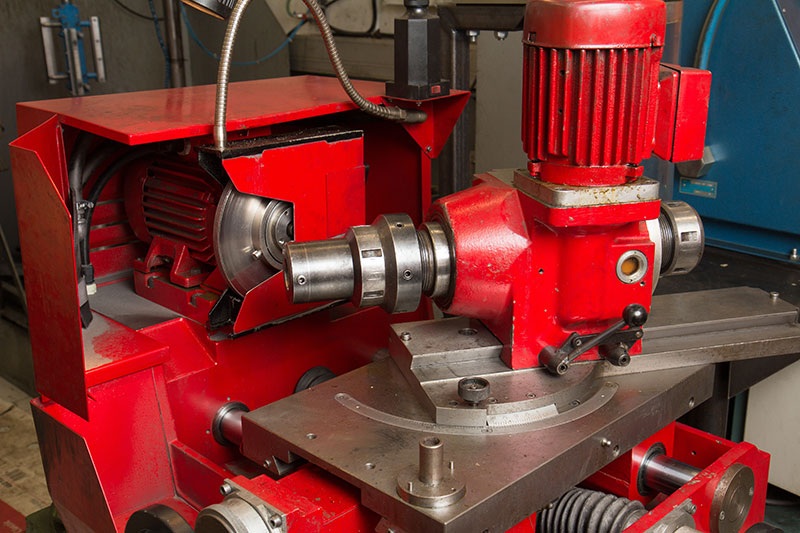

Honing machine

| Usage | Technical description |

|---|---|

| Precision surface finishing of liners (cylinders) to ensure lubricating oil adhesion. | The equipment can be used both on-site, where the engine is located, and in a workshop. Suitable for cylinders with diameters ranging from 150 to 600 mm. |

Ultrasonic cleaning of metal and mechanical components.

| Usage | Technical description |

|---|---|

| Water, soap, and powerful ultrasonic waves break down tough and hard-to-reach dirt in engine components, including deposits in cooling systems and intercoolers. | The washing tank measures 160 cm in length, 80 cm in width, and 80 cm in depth. |

Injector test pump

| Usage | Technical description |

|---|---|

| Comprehensive testing of most standard fuel injectors (nozzles). | Leak testing and pressure testing, operational testing. |

Bending gauge

| Usage | Technical description |

|---|---|

| Bending measurements performed on crankshafts, for example before and after dry-docking. A simple and quick method for monitoring and assessing engine condition. | Measurement accuracy: 0.001 mm. Measuring range: 60–574 mm. Digital results. |

Valve grinding machine

| Usage | Technical description |

|---|---|

| Valve grinding machine. | For stems up to 50 mm, valve diameters up to 250 mm, and valve seats up to 310 mm. |

Hydraulic torque wrench

| Usage | Technical description |

|---|---|

| A hydraulic torque wrench is used to tighten bolts and nuts in a safe and highly precise manner. Powered by an electric hydraulic pump. Ideal for situations where accurate and secure torqueing is critical under demanding conditions, for example in power plants, bridge construction, wind turbines, towers, heavy industry, machinery, and gear systems. | For nuts and bolts up to 155 mm. Maximum torque output: 5,424 Nm at 690 bar. |

Washing machine for engine components

| Usage | Technical description |

|---|---|

| Removes all oil, dirt and loose paint from engine components with excellent results. |

Washes in a similar manner to a dishwasher, using boiling hot water and detergent. No solvents are used, and there is no risk of rust formation. Capable of cleaning equipment weighing up to 2 tons, with maximum dimensions of 179 × 179 × 120 cm. |

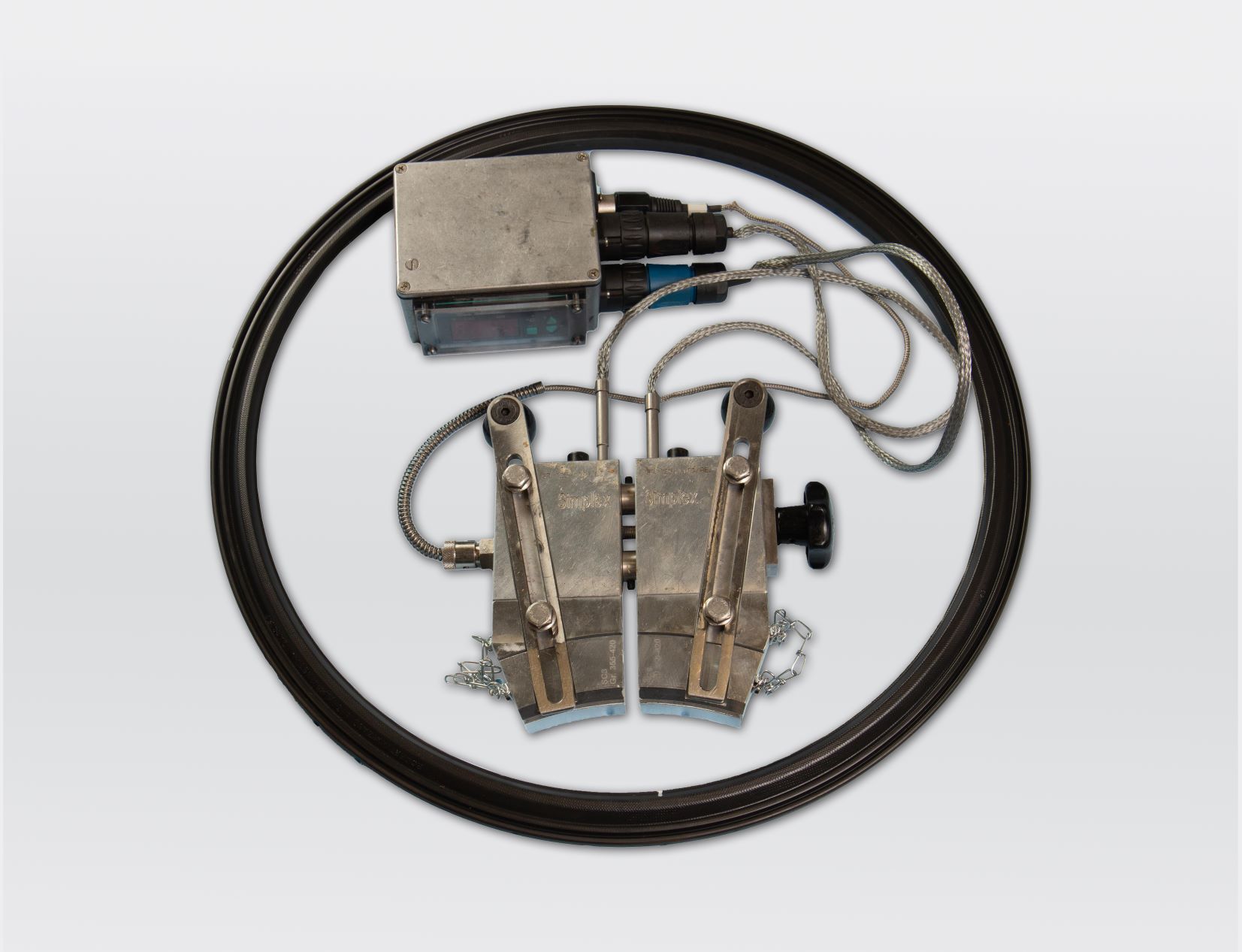

Simplex shaft seal

| Usage | Technical description |

|---|---|

| Héðinn is the only certified service provider for Simplex propeller shaft seals in Iceland. Héðinn’s Simplex specialists are trained by the manufacturer, SKF Marine, and have the specialized equipment and expertise required to carry out seal replacements. | Classification societies require that vessels undergo shaft withdrawal every five years. However, if an inspection shows the system is in good condition and the shaft seal is replaced, the shaft withdrawal may be postponed for an additional five years. |

CONTACTS

Send us a message

Fill out the Form